Coatings

- Beast SF

- Ceramics/Thermal Barrier

- Dry Film Lubricants

- ECTFE

- KECO Antimicrobial

- Plasma/Wire Arc

- Powder

- Teflon®

- Thermoplastic

- Urethane

- 2000 FRP

KECO Beast SF offers metal an enduring shield in climates with varying elements without impacting the environment. Flexible and resilient, the coating is BPA and VOC free. Providing exceptional opposition salt, sea, sand, and sun, the coating also repels vandalism and graffiti. Delivering outstanding coverage of edges and welds, KECO Beast SF makes it unnecessary to utilize a primer. In addition, in case of a fire, little smoke will result.

Available in a variety of colors, applications for KECO Beast SF include playground equipment, exterior furniture, fencing, handrails, and lighting columns.

If your coating needs requires these types of attributes, contact KECO at 800-336-5326 or keco@kecocoatings.com.

KECO’S ceramic coating family has the performance characteristics of a dry film lubricant and operates under extreme temperatures — when Teflon® and other coatings fail. Exceeding the limitations of polytetrafluoroethylene (PFTE) and resistant up to 1300° – 2000°F, KECO ceramic coatings are formulated for thermal barrier applications such as glass delivery and automotive exhaust systems (headers, intakes, and manifolds), as well as piston coatings, aiding in thermo-barrier protection.

KECO’s resin-bonded lubricant coating is designed to provide dry film lubrication for a variety of industrial, commercial, and military applications. The coatings provide solid film lubrication to meet the requirements for chemical resistance, anti-galling, and wear resistance of military specifications Mil-L-8937C and Mil-L-46010A.

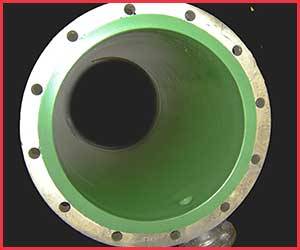

Designed to provide excellent chemical resistance in heavy-duty corrosion applications, KECO’S ECTFE (Ethylene ChloroTriFluoroEthylene) is suitable for protection and anti-corrosion applications as a result of its unique combination of properties. This product can be applied at different thickness variations to help with corrosion resistance and can be applied as a pin-hole free solution.

Deterring the growth of microorganisms, including viruses, bacteria, algae, and fungi, this coating provides long-term protection against corrosion. All metal substrates can be coated with KECO AM, as the technology inhibits bacteria from growing once applied. Available in a variety of colors, it can be applied to medical equipment, hospital furniture, food processing equipment, appliances, and more.

Plasma is a thermal spray, plasma, wire arc, metalizing, and flame spray. Applications include chromium carbide, chromium oxide, tungsten carbide cobalt, stainless steel, bronze, and many other metals designed for long-term performance. Formulated for thermal barrier and wear and surface restoration, KECO’s plasma coatings are also able to be machined once applied. Top coating can then be done if desired in several finishes to enhance longevity and offer many characteristics. Plasma coating applications can be sealed in silicone, urethane, Teflon, thermoplastic, and many other varieties.

A one-stop shop for powder coatings, KECO offers both conveyor and batch capabilities with excellent quality in a wide variety of colors, types, and finishes.

KECO has been applying Teflon® Industrial Coatings for nearly 30 years and is one of only 22 applicators in the United States licensed by DuPont. KECO’s portfolio consists of hundreds of fluoropolymer formulations including Teflon®, PTFE®, FEP® and Teflon® PFA® – designed to offer a wide range of nonstick attributes. KECO’s coatings will release virtually any substance including ink, glue, food, paint, varnish, adhesives, foam, rubber, and plastic. The applications include but are not limited to carbon steel, aluminum, stainless steel, brass, and glass.

Coatings that provide excellent wear, chemical, corrosion, and abrasion resistance, these are great in applications where part protection, sound deadening, and a more durable finish then a regular powder coat is needed. These coatings can be applied in several different applications.

Designed for corrosion resistance, durability, part protection, and wear resistance, these coatings are appropriate for vibratory feeder bowls, racks, dust collectors, and cyclones, plus they can help control many caustic acid and saltwater corrosion problems. KECO’s urethane products will adhere to metal and most common surfaces and can be applied a various thicknesses.

2000 FRP, a coating process applied to composite materials after surface preparation, provides thermal stability and hardness, plus it offers excellent flexibility, abrasion resistance, and non-stick properties.

Properties

Industries

Our Company

Mission

KECO Coatings’ mission is to develop and apply superior coating technologies – that address and meet the challenges of the demanding and changing requirements of today’s marketplace – with quality assurance, reliability, competitive pricing and excellent customer service. It is the core of our operation and a commitment we have made to our customers.

Quality Assurance

KECO dedicates a significant amount of resources to guarantee the quality and reliability of our products. It is an integral part of our mission and substantiated through our ISO 9001:2015 certification.

Please fill out the form below with your questions and contact information. We will contact you as soon as possible. Feel free to attach any drawings or pictures.

The more information you provide, the better we can answer your questions.